Novel Tricontinuous 3D Bulk Nanocomposites for Energy Applications

Students involved:

PhD students: Sam Welborn, Alexander Ng

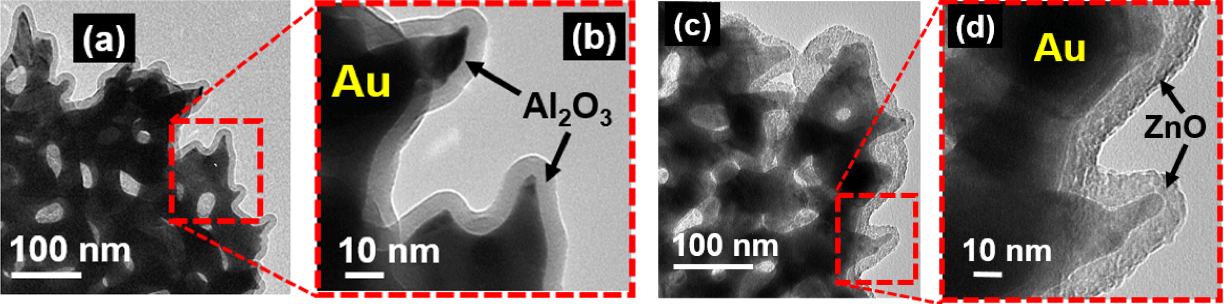

It goes without saying that the increasing miniaturization of conventional electronic components based on a 2D planar interface for charge transfer is approaching its limit. The new challenge is to further reduce the size of electronic components while preserving their performance. The 3DAFSN Lab is exploring alternative approaches for further miniaturization taking advantage the high surface-to-volume ratio of 3D bulk nanoporous materials. An ongoing project in our lab corresponds to the development of 3D solid-state nanobatteries and 3D nanocapacitors using atomic layer deposition (ALD) techniques to grow these devices in nanoporous metals scaffolds (See Figure 1).

Reference: S.S. Welborn, S. van der Meer, J.S. Corsi, J.T.M. De Hosson and E. Detsi (Under review).

Figure 1: (a, b) Al2O3 layer at different magnifications deposited by ALD on a nanoporous gold scaffold. (c, d) ZnO layer at different magnifications deposited by ALD on a nanoporous gold scaffold.

Figure 1: (a, b) Al2O3 layer at different magnifications deposited by ALD on a nanoporous gold scaffold. (c, d) ZnO layer at different magnifications deposited by ALD on a nanoporous gold scaffold.Lead Student: Sam Welborn, Alex Ng

Reference: S.S. Welborn, S. van der Meer, J.S. Corsi, J.T.M. De Hosson and E. Detsi (Under review).

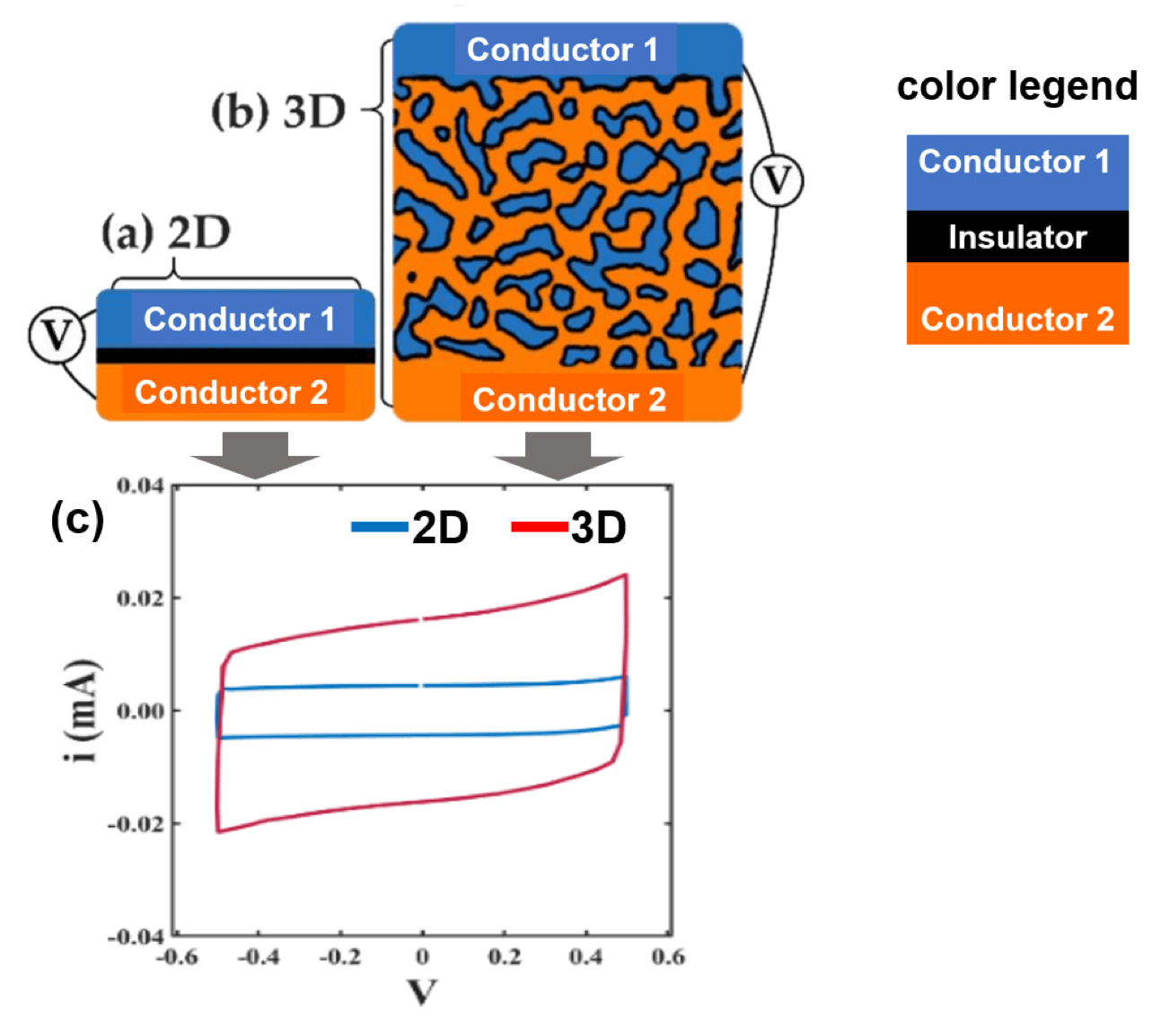

Using this approach, we have developed the 1st 3D tricontinuous bulk conductor/insulator/conductor nanocomposite for electrical energy storage built on a 3D bicontinuous nanoporous gold scaffold (See Figure 2).

Reference: S.S. Welborn, S. van der Meer, J.S. Corsi, J.T.M. De Hosson and E. Detsi (Under review).

Figure 2: (a,b) CV performance of a 3D nanocapacitor (red) and its 2D counterpart (blue). Both devices have the same footprint area.

Lead student: Sam Welborn

Reference: S.S. Welborn, S. van der Meer, J.S. Corsi, J.T.M. De Hosson and E. Detsi (Under review).