Cryogenic and Operando Electron Microscopy

Studies of Alkali Metal Battery Electrodes

Students involved:

PhD students: John Corsi, Lin Wang, Yihui Zhang

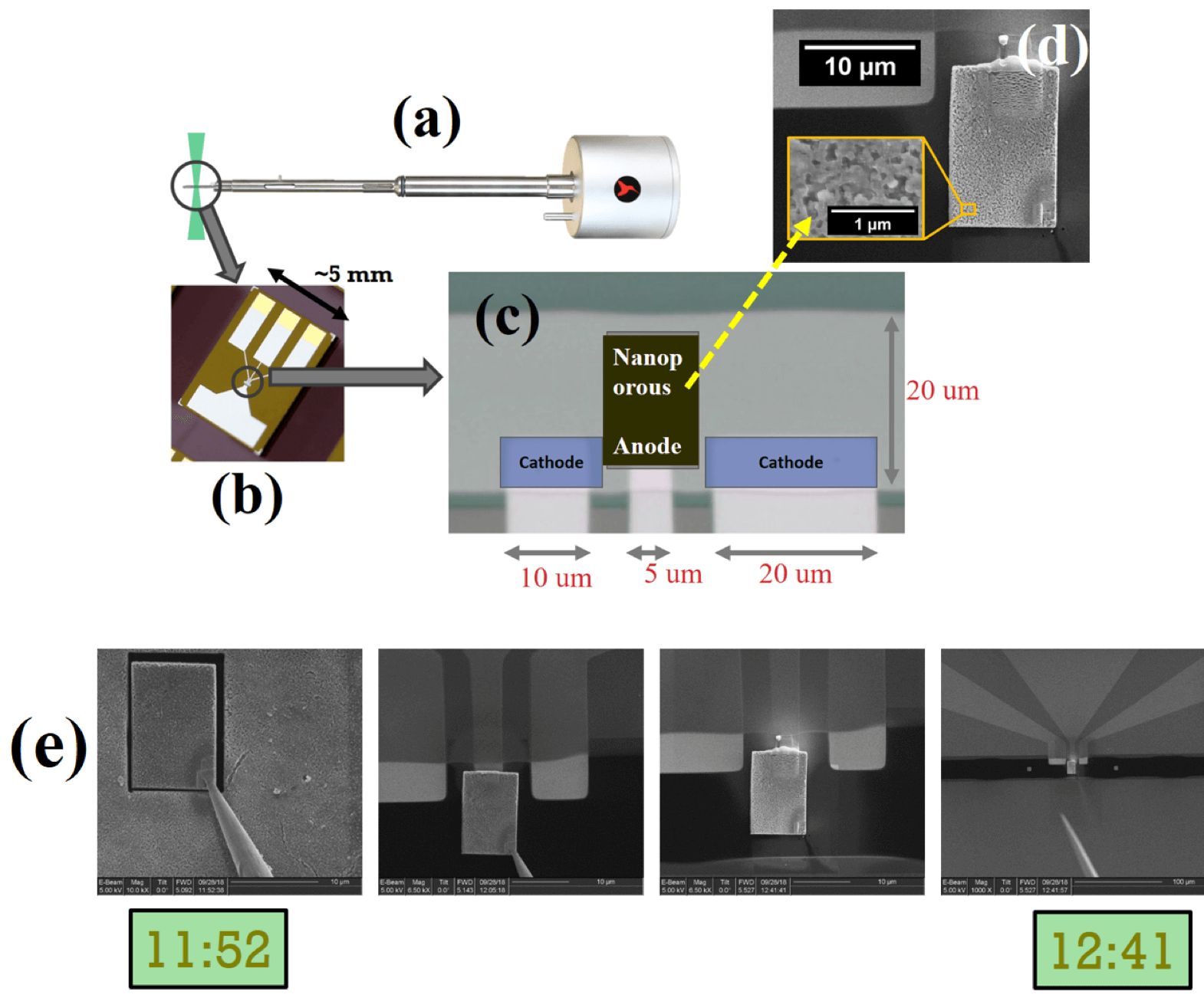

High-capacity alloy-type Mg-ion, Na-ion and K-ion battery anodes undergo large volume changes (~300%) during (de)magnesiation, (de)sodiation and (de)potassiation. The resulting stresses can cause pulverization of the active material and its delamination from the current collector, rendering it electrochemically inaccessible. Various works have demonstrated that the cycling performance of alloy-type anodes can be significantly improved using electrode materials having a nanoporous architecture. However, the mechanism through which the performance of a nanoporous electrode is enhanced is not fully understood. The 3DAFSN Lab/Detsi group in collaboration with the Stach group, both in the MSE department, work to shed new light on the morphology evolution and charge storage mechanism in alloy-type Mg-ion, Na-ion and K-ion battery anodes using state-of-the-art electron microscopy characterization techniques including: (1) cryo focused ion beam electron microscopy (Cryo FIB EM) to study air-sensitive anode materials and liquid anodes; (2) operando transmission electron microscopy (TEM) to study the morphology evolution in real time during charging and discharching using a Hummingbird Scientific bulk liquid electrochemistry TEM specimen holder (see Figure 1a). The operando TEM process involves building nanobatteries that operate inside the TEM holder. We use focused ion beam (FIB) to cut electron-transparent nanoporous electrode samples (see Figure 1d and 1e), which we position onto the TEM micro-chip and weld (see Figure 1e) using a micro-manipulator.

Figure 1: Setup for real-time TEM experiments. (a) Liquid-cell TEM holder. (b) Chip with micro-battery to investigate; (c) Micro battery electrodes in the chip; (d) High-magnification image showing the nanoporous electrode to store charge; (e) The nanoporous electrode was cut with FIB, and welded on the chip in less than 1 hour.

Figure 1: Setup for real-time TEM experiments. (a) Liquid-cell TEM holder. (b) Chip with micro-battery to investigate; (c) Micro battery electrodes in the chip; (d) High-magnification image showing the nanoporous electrode to store charge; (e) The nanoporous electrode was cut with FIB, and welded on the chip in less than 1 hour.Lead student: John Corsi.

Reference: J.S. Corsi, S. S. Welborn, E.A. Stach and E. Detsi